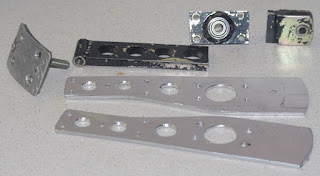

Today I finally got some half decent garage time & made up the pulley / lever. Seems to work quite well with 2mm aluminium plates bolted on either side of the pulley with a rod end one side of the lever & a "nipple clamp" made from an M8 bolt the other ("nipple clamp" because it clamps the cable & acts as a cable nipple at the same time).

Today I finally got some half decent garage time & made up the pulley / lever. Seems to work quite well with 2mm aluminium plates bolted on either side of the pulley with a rod end one side of the lever & a "nipple clamp" made from an M8 bolt the other ("nipple clamp" because it clamps the cable & acts as a cable nipple at the same time). I am a little concerned about the bearing strength of the 2mm aluminium, but it's all bolted together, so easy enough to re-make the plates in steel if it deforms - we'll see. I'll be doing LOTS of testing as soon as the weather warms up.

Next job is to make up the chassis mount to attach this bit to the car & make it all work.

Don't know if you can use this pic & the ones in the last post to see how this works, but the turnbuckle (the stainless cylinder) is pulled by the pedal (vertically down in this picture, that pulls on the lever attached to the pulley which rotates about the centre bolt. so the cable clamp is moved round the radius pulling the cable round the pulley as it goes. The other end of the cable is attached to the clutch lever in the conventional way. So the only metal to metal movement in the whole system will take place at bearings designed for the job. Should be good - fingers crossed

.